|

The impact of the epidemic on the manufacturing industryI. Foreword

The epidemic is rearing its head again in China, with repeated stoppages and production stoppages across the country, strongly affecting all sectors of life. At present, we can pay attention to the impact of the epidemic on the service industry, such as the closure of catering, retail and entertainment industries, which is also the most obvious impact in the short term, but in the medium term, the risk of manufacturing is greater.

The carrier of the service industry is people, which can be recovered once the epidemic is over. The carrier of the manufacturing industry is goods, which can be maintained by inventory for a short period of time. However, the shutdown caused by the epidemic will lead to a shortage of goods for a period of time, which will lead to the migration of customers and suppliers. The medium-term impact is greater than that of the service industry. In view of the recent large-scale resurgence of the epidemic in parts of China, such as east China, South China and northeast China, what kind of impact has been caused by the manufacturing industry in each region, what kind of challenges will be faced by the upper, middle and lower reaches, and whether the medium and long term impact will be amplified? Next, the author will analyze one by one through Mysteel's recent manufacturing survey.

II. Macro brief introduction

The manufacturing PMI in February 2022 was 50.2%, up 0.1 percentage points from the previous month. The non-manufacturing business activity index was 51.6 percent, up 0.5 percentage points from the previous month. The composite PMI was 51.2 percent, up 0.2 percentage points from the previous month. There are three main reasons for the PMI's rebound. First, China has recently introduced a series of policies and measures to promote the steady growth of the industrial and service sectors, which has improved demand and increased order indices and business activity expectation indices. Second, increased investment in "new infrastructure" and accelerated issuance of special bonds led to a marked recovery in the construction industry. Third, due to the impact of the Russia-Ukraine conflict, the price of crude oil and some industrial raw materials soared recently, resulting in the rise of the price index. Three PMI indexes rose, indicating that momentum is returning after the Lunar New Year holiday.

The return of the new orders index above the expansion line indicates improved demand and a recovery in domestic demand. The index for new export orders rose for the second month in a row, but remained below the line separating expansion from contraction.

The expectation index of manufacturing production and business activities rose for four consecutive months and hit a new high in nearly a year. However, the expected operating activities have not yet been translated into substantive production and operation activities, and the production index has fallen seasonally. Enterprises still face difficulties such as rising raw material prices and tight cash flow.

The Federal Reserve's Federal Open Market Committee (FOMC) on Wednesday raised the federal benchmark interest rate by 25 basis points to a range of 0.25%-0.50% from 0% to 0.25%, the first increase since December 2018.

III. Downstream terminal industry

1. Overall strong operation of steel structure industry

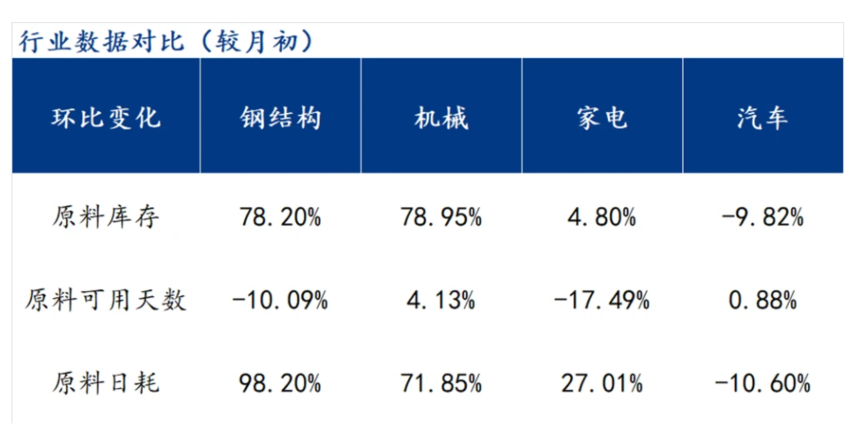

According to Mysteel research, as of March 16, the steel structure industry as a whole raw material inventory increased by 78.20%, raw material available days decreased by 10.09%, raw material daily consumption increased by 98.20%. In early March, the overall terminal industry demand recovery in February was not as good as expected, and the market was slow to warm up. Although shipment was slightly affected by the epidemic in some areas recently, the process of processing and start-up was greatly accelerated, and orders also showed a significant rebound. It is expected that the market will continue to improve in the later period.

2. Machinery industry orders gradually warm up

According to Mysteel research, as of March 16, the inventory of raw materials in the machinery industry increased by 78.95% month-on-month, the number of available raw materials increased slightly by 4.13%, and the average daily consumption of raw materials increased by 71.85%. Order according to Mysteel research for mechanical enterprises, the industry is good, but influenced by parts factories have closed nucleic acid detection, more severe epidemic area such as guangdong, Shanghai, jilin has the seal factory situation, but the actual production is not affected, most of the finished product into the library after being unsealed, so current machinery industry demand of short duration is not affected, And it is expected that orders will increase significantly after unsealing.

3. The home appliance industry as a whole runs smoothly

According to Mysteel research, as of March 16, the inventory of raw materials in the home appliance industry increased by 4.8%, the number of available raw materials decreased by 17.49%, and the average daily consumption of raw materials increased by 27.01%. According to our survey of the home appliance industry, compared with the beginning of March, the current home appliance orders have begun to warm, the market is affected by the season, weather, sales and inventory are in the stage of gradual recovery. At the same time, the home appliance industry focuses on continuous research and development to create more reliable and high-performance products, and it is expected that more efficient and intelligent products will appear in the later period.

4. The auto industry is down

According to Mysteel research, as of March 16, the auto industry raw material inventory decreased 9.82% month-on-month, inventory available days increased 0.88% month-on-month, raw material available days decreased 10.6% month-on-month. Different from other terminal industries, the automotive industry has not increased significantly in the past half a month, and the problem of chip shortage in cars still exists. According to our survey of some auto companies and auto parts manufacturers, the overall production of enterprises is not affected by the epidemic, and only a small number of manufacturers cut down some production lines, so the operation of the auto industry has not changed much from the beginning of March. However, from the perspective of automobile orders, the new orders of the automobile industry in March turned positive month-on-month, and the production saturation of dealers improved significantly.

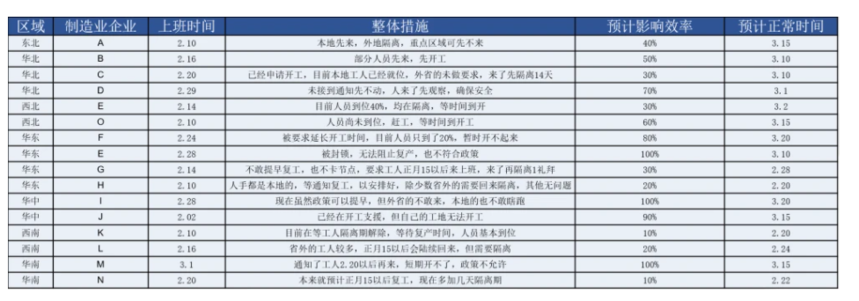

IV. Impact of the epidemic on downstream enterprises and their expectations

According to Mysteel's research, there are several problems facing downstream:

1. Policy impact; 2. Insufficient personnel; 3. Reduced efficiency; 4. Financial pressure; 5. Transportation problems

In terms of time, compared with last year, it takes 12-15 days for downstream impacts to resume work, and it takes longer for efficiency to recover. Even more worrying is the impact on manufacturing, with the exception of infrastructure-related sectors, it will be difficult to see any meaningful improvement in the short term.

IIV. the summary

Overall, the impact of the current outbreak is modest compared to 2020. From the production situation of steel structure, household appliances, machinery and other terminal industries, the current inventory has gradually returned to normal from the low level at the beginning of the month, the average daily consumption of raw materials has also increased significantly compared with the beginning of the month, and the order situation has picked up greatly. Automotive industry, auto chip shortages still exist at present, but the order is still hot, new energy vehicles in the east China area, for example, part of the new energy brand under the condition of the price and delay for the order is still hot, so effectively alleviate once chip problem, the future market will continue to improve. On the whole, although the terminal industry has been affected by the epidemic recently, the overall impact is not significant, and the recovery speed after unlocking may exceed expectations. |